Description

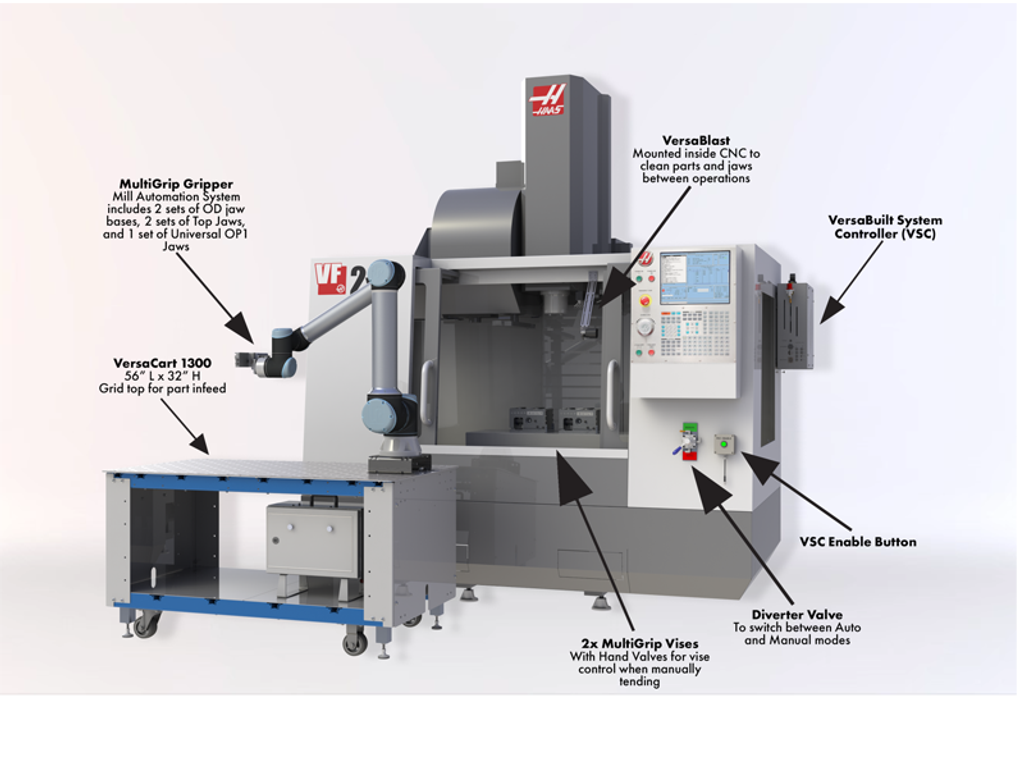

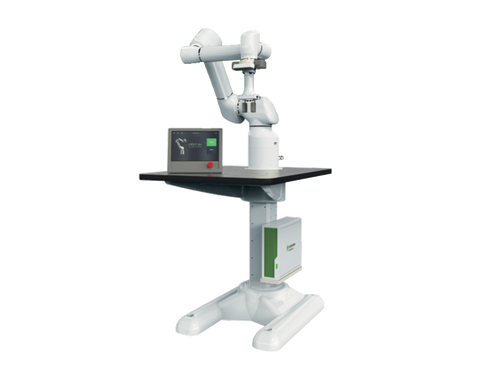

The VersaBuilt Mill Automation System with Multi-Grip automation workholding allows your machinists to easily add new parts just by cutting vise soft jaws and entering parameters on a web page. Only Multi-Grip has an effective solution to the difficult problem of Op 1 to Op 2 transfer in CNC milling automation. The result: longer automation run times, and more production with less labor. At VersaBuilt, we understand machine shops have been struggling to find CNC automation solutions that fit their high-mix production needs. Most machine shops do not have the time or expertise to perform complex robot integrations. That’s why we build automation solutions designed to be used by your existing machinists and operators that require no robot programming and are able to thrive in the most demanding high-mix CNC shops—maximizing the value of your automation investment.

VersaBuilt customers typically report a doubling of production output using half the labor.

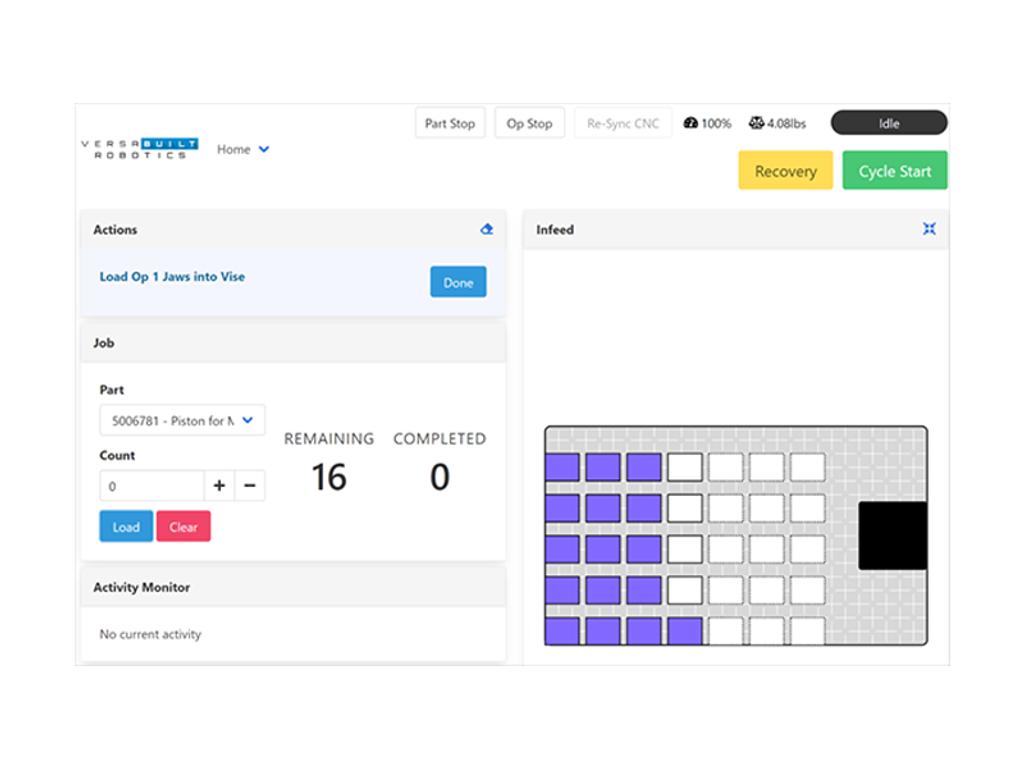

No Robot Programming Required - Easy-to-use automation software designed from the ground-up for CNC milling automation. All robot motion is pre-programmed yet fully customizable. Simply enter part dimensions and CNC milling program numbers, and enjoy the benefits of CNC automation. The VersaBuilt CNC Mill Automation System is the easiest and most capable CNC machine tending system available.

Perfect for High-Mix Production - Configuring new parts for automation has never been easier or faster—Perfect for high-mix production! The Mill Automation System allows a machinist to configure a new part in just a few minutes. Using a web-based form, the machinist inputs part configuration parameters. Once the part configuration is saved, the CNC operator can select a saved part configuration, and the software will show the operator exactly where to load material onto the VersaCart 1300. Once the material is loaded and part quantity is entered, pressing the cycle start button begins the automation process.

Made For Your Multi-Operation Parts - Your parts require multiple operations; why settle for a milling automation system that doesn’t support multiple operations? Only VersaBuilt’s patented MultiGrip automation workholding system provides a generalized solution for multi-operation CNC milling automation. There is no easier, faster way to automate your CNC milling production.

Ready To Produce In 1 Day - The whole CNC Mill Automation System can be installed and running parts in just one day. Our system is a ready-to-go product made by machinists for machinists to get your automation running faster than any other automation system available.

Quality In-Depth Training And Support - The Mill Automation System includes in-depth training courses tailored to the operator, machinist, and installer. The classes will take place over a video conference call and will typically last one to two hours each. This training will get your team and new system ready to automate as soon as possible.

Top Features Of The CNC Mill Automation System

We understand industrial CNC milling machines, so this is why our milling solution includes everything you need to get to automated production fast and easily.

-

VersaCart 1300 - Portable cart optimized for the Universal Robots UR10e robot

-

Visual Infeed System - Part alignment grid improves operator efficiency and maximizes infeed capacity over a wide range of part sizes

-

2x MultiGrip Vises - Easily automate part processing through multiple milling operations

-

MultiGrip Robot Gripper - Machine tending specific gripper that has 200lbs clamping force and supports 10kg part payload.

-

VersaBlast in-CNC Cleaning - Removes chips and coolant from parts and MultiGrip jaws after machining

-

VersaBuilt System Controller (VSC) - CNC automation Control System provides rich graphical user interface and coordinates all CNC, robot, and I/O functions simplifying installation and eliminating the need for tedious robot programming

-

MultiGrip Jaws Starter Kit - Include ready-to-go Top Jaws (2ea) and MultiGrip Base Jaws OD (2ea)

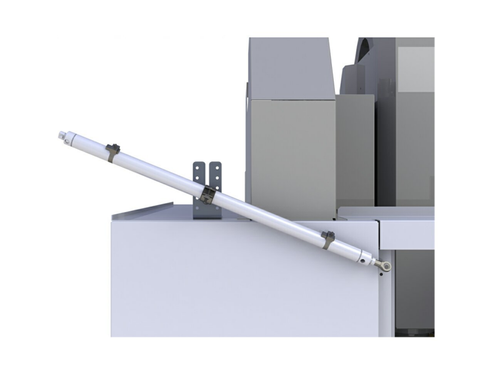

Optional VersaDoor - Simple and reliable automatic door opener for CNC available for single or double doors

Optional VersaWash - improves automation cycle efficiency and results in cleaner completed parts on the table. Because the VersaWash uses water to remove coolant and chips, completed parts are cleaner when placed back on the VersaCart. Moving the chip cleaning step from inside the CNC to outside the CNC means the CNC can get back to cutting parts sooner, increasing productivity.

DOWNLOADS:

Mill Automation System Data Sheet

Reviews (0)

Be the first to review this product.

Additional Info

- SKU:

- VERS-5010049

- Shipping:

- Calculated at Checkout