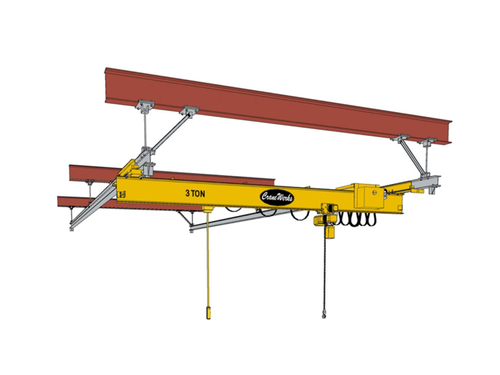

Description

Generally a lot lighter than a top running system, under hung crane runways allows for more versatility. Underhung bridge cranes are typically used for lighter applications; under 20 tons. These systems can be mounted from the ceiling or interlocked together. Because the bridge runs underneath the runway rail, multiple systems can be ran side-by-side without interfering with one another. Along with top running manual cranes, underhung single girder push cranes are the least expensive bridge cranes available and they have a better trolley end approach compared to a top running manual crane. The durable easy to operate manual bridge crane can be equipped with an electrical festoon wire or an air hose to provide power to your desired lifting apparatus.

Capacities: up to 15 tons (hand chain recommended over 2 tons)

Bridge Span Lengths, overall: up to 45'

Runway Spans: determined by structure

Height — Floor-to-Trolley Clevis: determined by structure

Push/Pull Manual Underhung Cranes Features:

- Inexpensively manipulates light loads with spans up to 45 ft.

- Best used where crane operating heights are 15 feet and below.

- Due to the applied force that is needed to move the bridge crane, some conditions may not be conducive to this type of system including slick floors and areas with many floor obstructions.

- Exceptional speed control.

Design Details

One of the great advantages of push/pull type overhead bridge cranes is their great speed control. Push/pull cranes accelerate and decelerate at the speed of the operator. This can be more efficient in many cases than handling the same loads with powered (motorized) cranes that have set speed points.

Standard I-beam constructed underhung push/pull manual cranes are the most economical bridge cranes available; however, easier to push/pullpatented rail and enclosed rail cranes are available where high and repetitive uses of the cranes are called for. These overhead bridge cranes (though often more expensive than I-beam) can be moved with 1/3 the amount of effort and they have excellent durability.

Hand Chain Drive Manual Underhung Cranes Features:

- Inexpensively moves loads up to 15 ton.

- Enables precision spotting.

- Use for pumping stations, assembly applications, and maintenance bays.

Design Details

Chain driven bridge cranes are operated by pulling the hand chain that drives the geared wheels in one direction or another to move the bridge crane. While this gearing makes it easier to move loads than a push/pull system it also makes the operation relatively slow. This makes positioning a load in a precise location much easier.

In general underhung manual overhead bridge cranes are less expensive than top running cranes of the same capacity, yet they are durable and easy to operate.

Manual bridges work well with manual chain hoists, air hoists, electric hoists, and air balancers. Each crane can be equipped with an electrical festoon wire or an air hose to provide power to your desired lifting apparatus.

Reviews (0)

Be the first to review this product.

Additional Info

- SKU:

- RQ-CRAS-UHSGMBC

- Availability:

- Call for Lead Time

- Standard Capacities:

- Up to 15 tons

- Spans:

- Up to 45 ft. (Bridge Length)

- Heights:

- Determined by structure

- Power Option:

- No

- Mounting:

- Underhung