Description

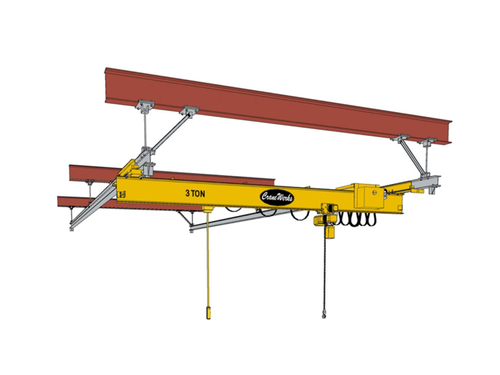

Generally a lot lighter than a top running system, underhung crane runways allow for more versatility and usability. Because they’re dramatically lighter, underhung runways can be ceiling-mounted. They also have the ability to run side-by-side without interfering with one another. Another mechanical advantage of underhung crane systems is their ability for multiple systems to be interlocked, enabling operators to transfer loads between them. They can also interlock with monorails, allow for material transfer along a fixed path. CraneWerks underhung freestanding runways feature a bolt-together construction which doesn’t require a certified welder for assembly. One of the major advantages of an underhung crane is its ability to interlock with a fixed spur, crossover, and adjacent cranes. This interlocking capability allows a load to be transported throughout the plant system without the need to set it down, thereby eliminating re-handling.

Capacities: up to 15 tons

Bridge Span Lengths, overall: up to 60' (standard)

Runway Spans: unlimited

Height — Floor-to-Trolley Clevis: customizable

Features:

- Bolt-together construction requires no certified welder.

- Normally range from ½ to 15 Ton capacity.

- Standard spans up to 55 feet.

- Unlimited lengths available.

- Accommodates transfer switches

- Columns bolt to as small as a 6 inch concrete slab or reinforced concrete footer.

- Motorized, hand chain, push type, and pneumatic powered bridge cranes available.

- Standard systems are pre-engineered.

- Ships complete with:

- assembly manual

- runway electrification

- hardware

- Chemical anchors are provided when foundations are not needed.

- Computer aided design drawings supplied.

- Designs are based on AISIC specifications.

Design Details

Underhung runway systems are designed to support the stand alone workstation bridge crane from the lower flange of the runway girder. These girders are commonly constructed from I or W flanged beams. Heavy duty patented track runways are available for high usage applications. Patented track is fabricated with a hardened lower flange to resist wear. Both underhung runways and monorail spurs can use the same track; therefore, they can be interconnected as a cost effective means of transferring loads between building bays via transfer switches. Click here for more information on underhung bridge cranes with switches. By design, nothing inherent to the freestanding system obstructs the path of the runway and extending the system is simple.

Multiple Cranes Sharing the Same Runway

Many times the most practical use of a runway is to utilize it to support more than one overhead bridge crane. Large and uneven loads can often be lifted when this is a requirement with two similar or different capacity cranes. Also one runway can support multiple bridge cranes and service various work cells located along the length of a bays runway. In this case for example you could have a 10 Ton runway system and have 5 five Ton overhead bridge cranes running on the 10 Ton runway by creating zones within each cell that cranes can travel in but not travel out of.

Sophisticated load summing controls are available that will even monitor the loads of multiple cranes operating on a common runway. This is particularly useful when you need the added flexibility of using many bridge cranes and to protect your runways from overloads that could lead to unsafe usage by the crane operators.

Beside electronic limiting devices please feel free to inquire of our application engineers about many different standard and custom mechanical devices that are available to allow many overhead bridge cranes to be used safely on a single runway.

Applications:

- Die manipulation and repairs

- Plastic molding

- Steel fabrication

- Handling material

- Burn tables

- Burial vault manufacturing

- Concrete pipe and burrier manufacturing

- Food grade stainless steel equipment available for food the pharmaceutical industries

Reviews (0)

Be the first to review this product.

Additional Info

- SKU:

- RQ-CRAS-UHFBCR

- Availability:

- Call for Lead Time

- Standard Capacities:

- Up to 15 tons

- Spans:

- Up to 60 ft. (Bridge Length)

- Heights:

- Customizable

- Power Option:

- Yes

- Mounting:

- Top Running