Description

Get Fast & Easy Retrofit Financing

![]()

Get instant funding with low monthly payments

Get instant funding with low monthly payments

Unfortunately we do not perform retrofits outside of the United States, Canada, and Mexico at this time

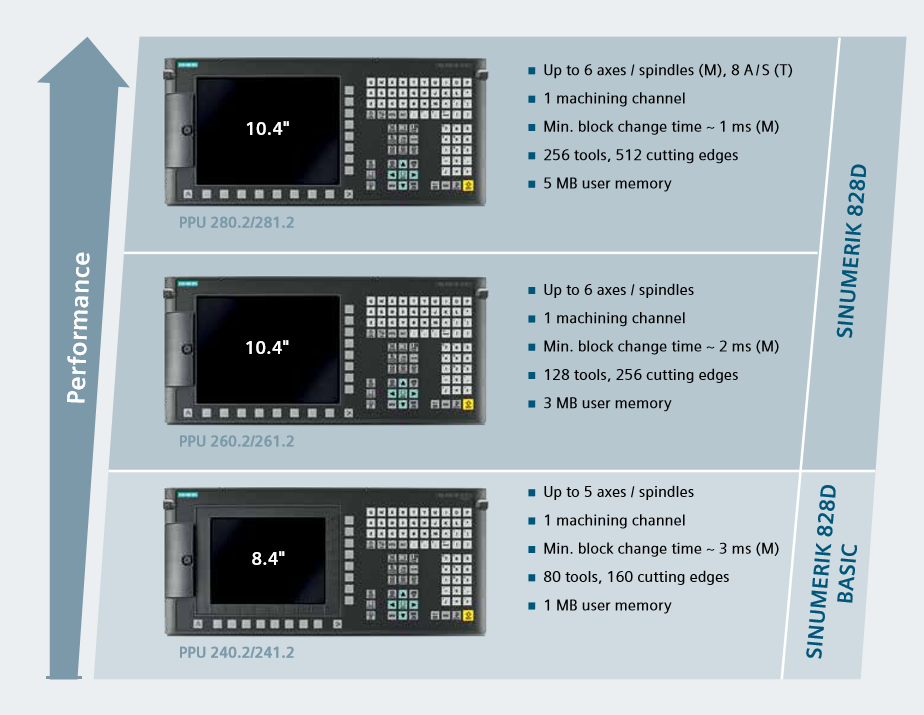

Bring your shop up to speed with a new Siemens SINUMERIK 828D CNC System. The Siemens 828D control is idealfor standardized turning,milling and grinding machines. The SINUMERIK 828 is capable of handling a range of applications, which extendsfrom vertical and basic horizontal machining centers –naturally also for moldmaking applications – throughsurface and cylindrical grinding machines up to twochannelturning centers with counterspindle, driven toolsand Y-axis. Rugged hardware architecture and intelligentcontrol algorithms, along with premium drive and motortechnology, ensure the highest dynamic response andprecision when machining. The intuitive SINUMERIKOperate user interface facilitates efficient machine operation.With their outstanding performance, SINUMERIK 828controls master all of the demands for standardizedturning, milling and grinding machines.

Siemens 828D offers optimum scalability in the compact class

SINUMERIK 828 –first choice for every machining technology

Turning

4-axis turning is possible using two tools that operate independently ofone another – also known as balance cutting. Just some of the new functionsinclude multi-channel operation with ShopTurn, which also allowsprograms to be synchronized using programSYNC. The new 28x softwareallows simultaneous operation in two channels for lathes and grindingmachines.

Milling

When it comes to milling, optimum workpiece surfaces are achieved withthe highest machining speed based on Advanced Surface (standard) andTop Surface (optional) with intelligent motion control. CAD data is verysimply transferred into the CNC program using DXFreader. The measurekinematics cycle (CYCLE996) has been developed to measure multi-axiskinematics, and can be directly called from the NC program. 3D simulationat the PC facilitates improved control and optimization of the productionprocess.

Grinding and additional technologies

Grinding machines can be very simply commissioned by pre-assigningtechnological data. The new basic functions include automated measuringand setting up of grinding machines, additional grinding parameters formanaging contour, dressing program and grinding tools – as well as standardgrinding cycles and grinding-specific NC functions. Advanced functionsensure a higher quality and productivity. Further, using HMI Universal,the software can also be used for other applications.

SINUMERIK CNC performance –the machining standard

Highest precision

SINUMERIK CNCs and SINAMICS drives compute with high-performance80-bit NANOFP accuracy. This eliminates rounding errors and results in anextremely high internal computational accuracy in the complete controllercircuit. Further, a dynamic feed forward control ensures that the followingerror is almost completely compensated – and jerk limitation reduces stresson the mechanical system when axes accelerate. Using its Dynamic ServoControl, SINAMICS control technology provides additional position controlin the drive – representing an additional advantage by achieving anincreased level of disturbance resistance of the machine control.

Maximum speed

When machining many CNC blocks in the shortest time, for example, freeformsurfaces, the machining process itself no longer defines the speed,but the performance of the CNC. Here, with its Advanced Surface and TopSurface features, SINUMERIK offers the ideal solution. Advanced Surfacestands for state-of-the-art control algorithms, such as Look Ahead or thedynamic compression of linear and circular blocks in 5th degree polynomials(NURBS). Machines can be operated at their physical limits whenusing Advanced Surface and Top Surface.

Shortest idle times

Especially in large series production, idle times, where the machine is nolonger productive, represent a critical productivity-inhibiting factor. Here,SINUMERIK provides the optimum solution with its synchronous architectureand intelligent functions, such as synchronized actions and asynchronoussubprograms. For example, loading equipment can be implementedwithout having to make time-consuming changes to the PLC program.

To learn more check out the Siemens 828D CNC Brochure

Maintenance and Customer Support

As an integrator we have completed hundreds of retrofits in the United States, Mexico, and Canada. We are extremely proud of the fact that we don't just offer machine tool retrofits - we offer turnkey solutions that leave our customers with little to do when it comes to retrofitting their machines. All of our CNC retrofit solutions include factory warranty on all hardware - including CNC, drives, and motors. We also offer 24/7 support for the life of the control system, so you can be sure that you'll have the support you need to keep your machine up and running.

Request a Free Quote

We would love to work with you on your next retrofit project. To receive a free quote for a turnkey Siemens CNC retrofit solution, please click the red "Request Quote" button above and provide your contact information and a brief overview of your retrofit application. Once we receive your RFQ one of our Controls Engineers will contact you to discuss your application in more detail. We look forward to working with you!

Reviews (0)

Be the first to review this product.

Additional Info

- Warranty:

- <a href="http://machinetoolproducts.com/content/Siemens/828D/Siemens%20828D%20CNC%20Brochure_2017.pdf" target="_blank">Siemens SINUMERIK 828D CNC Brochure</a>

- SKU:

- TKR-SIEMENS-828D

- Availability:

- 10-14 weeks (expedite services available)