Description

Interested in our "Try-Before-You-Buy" Program? CLICK HERE

OB7 Collaborative Robots bring home the competitive edge for job shops and large machine shops. A game changer for machine shops, OB7 CNC tending robots load blanks and unload finished parts, keeping your machines running 100% of the time. With zero breaks or distractions, OB7 minimizes downtime and ensures consistent quality machine output on your shop floor. OB7 works one, two, or three shifts, gaining up to 24 hours ‘lights out’ operation. Simply roll OB7 up to your CNC mill, lathe, or other machine and go. OB7 operates any brand of machine. With zero complicated software programming, OB7 allows you to automate instantly and achieve an immediate return on investment, while opening up new productivity horizons.

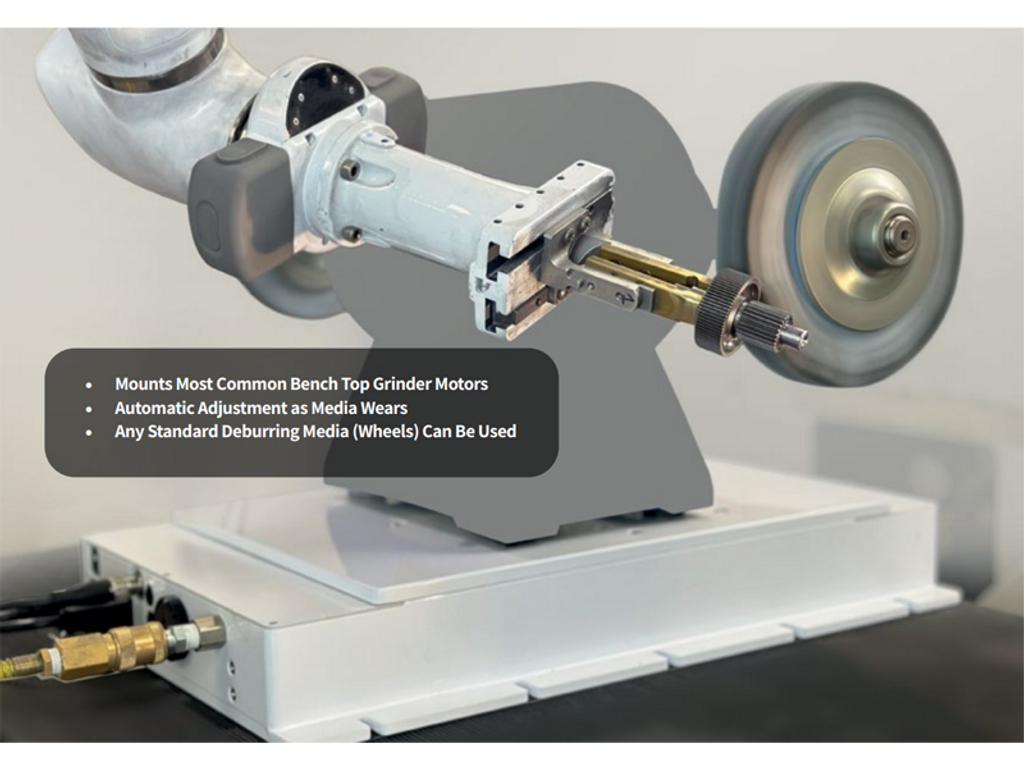

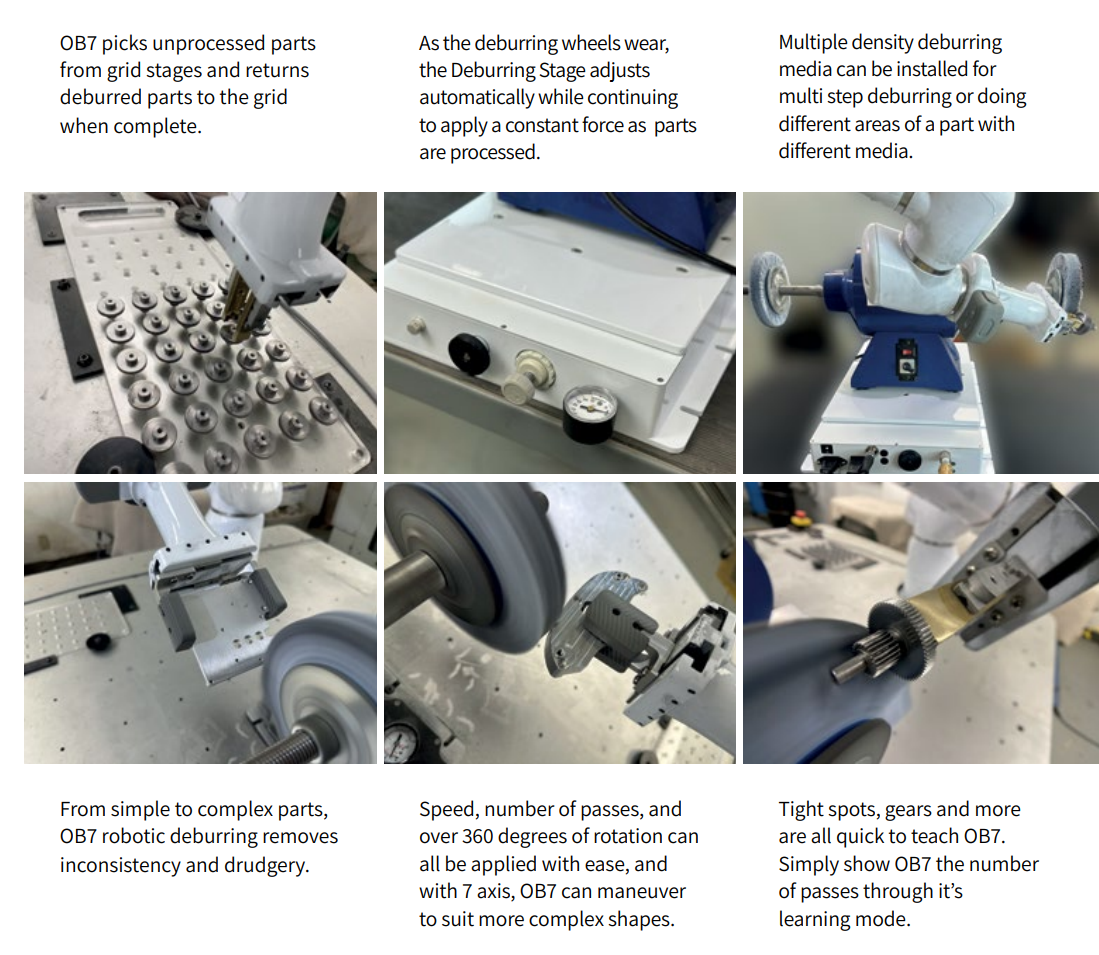

In operation, the Deburring Stage applies constant force to the part while the OB7 robot guides it along the deburring media. Constant force is maintained as the deburring wheels wear. The deburring motor is controlled by the OB7 robot.

NO INTEGRATION REQUIRED - Installation is fast and simple, in as little as a few hours.

UNMATCHED AUTOMATION PRODUCTIVITY, ACCURACY AND SAFETY FOR LESS THAN $5/HOUR.

DESIGNED AND BUILT IN THE USA

Run 24/7 ‘Lights Out’ - Designed to tirelessly run ‘lights out’ shifts, OB7 loads blanks and unloads finished parts consistently 100% of the time. With zero breaks or distractions, OB7 minimizes down time and ensures consistent, quality output.

Machine Tending Without Programming - OB7 Learns by Doing. Not Coding. Use the control handle to physically teach OB7 robots without programming or learning any techie jargon. Set details on the Control Tablet with Productive Robotics’ famous drag and drop display. Productive Robotics’ “No Programming” system allows anyone to easily and quickly automate any shop task, regardless of robotics experience.

7-Axis Extreme Maneuverability - Unmatched by any 6 axis robot - Like a human arm, seven joints give OB7 robots the flexibility to operate in a confined space and reach around obstructions, such as a machine tool’s sliding door. It allows the operator access to do maintenance, setups and tool changes without blocking access to the machine.

DOWNLOADS: Machine Shop Brochure (Specs) CNC Machine Tending Brochure Capitalize on your Cobot

Features

- Mounts Most Common Bench Top Grinder Motors

- Automatic Adjustment as Media Wears

- Any Standard Deburring Media (wheels) can be used

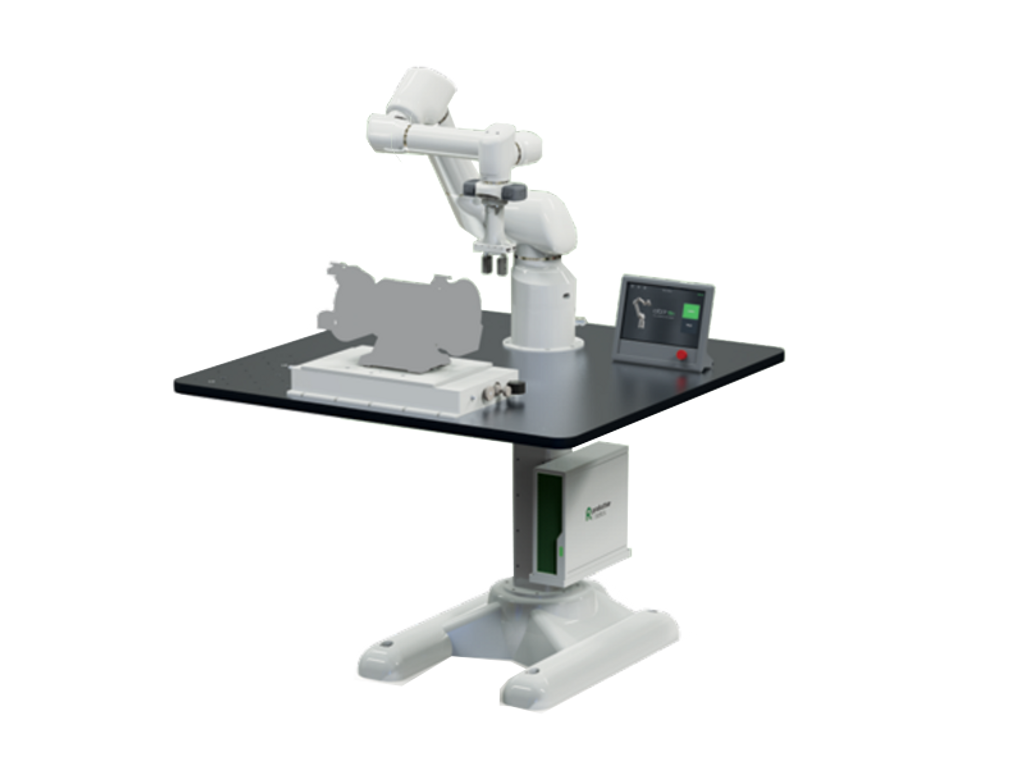

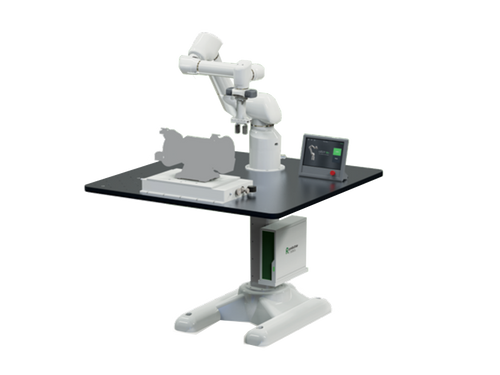

ALL-INCLUSIVE PACKAGE:

• OB7, Stretch, Max 8 or Max 12 Robot

• Controller & Tablet

• Robot Stand

• Assembly & Staging Table 47”x47”

• PG2 Parallel Programmable Electric Gripper

• Robot Machine Interface

• Deburring Stage

• All necessary cables

Sizing:

OB7 = 5kg Payload, 1m Reach

OB7-Stretch = 4kg Payload, 1.25m Reach

OB7-Max12 = 12kg Payload, 1.3m Reach

OB7-Max8 = 8kg Payload, 1.7m Reach

"Since adding six robots, we haven't leg go of a single person. We've actually ramped up our workforce." - ABACORP

"We gained many benefits with OB7, including operator happiness, greater productivity of at least 20%, more parts being made, fewer scrapped parts, improved part quality, faster delivery times and more competitive pricing when we quote on new jobs." - B.I.C. Precision

"Working 'lights out' with OB7 allows us to go home and return the next morning with a job completed, ready to start the next. OB7 has saved us significant time and money, while increasing quality and precision." - Swiss Productions

Options:

• OB Vision

• Laser Safety Scanner

• Dual Parallel Gripper

• Additional I/O

• Pneumatic Controller

Reviews (0)

Be the first to review this product.

Additional Info

- SKU:

- PROS-DEBUROB7

- Shipping:

- $0.00 (Fixed Shipping Cost)