Shop Newall Lathe Digital Readout Kits

Efficiency. Accuracy. Productivity.

Common Problems for Lathes Without Digital Readouts

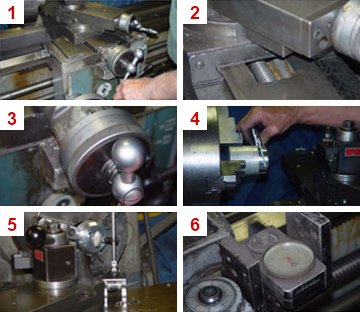

1. Cross-Slides Have Backlash

Lathes utilize a cross-slide to machine critical O.D. and I.D. dimensions.

2. Tool Pressure Is Exerted On The Cross-Slide

The turning work piece exerts pressure on the tool, which shifts the crossslide back against the screw. With backlash always a consideration, each lathe requires its own “feel.

3. Vernier Dials Are Hard To Read

The lines of the dial are hard to see and can be obscured by oil and debris. Hand wheel revolutions must be counted. Misreading of the dial and scraping the part is easily done if not extremely careful.

4. Stop And Check Time is Non-Productive

Since the operator cannot rely on the cross-slide dial for finish dimensions, frequent stops to check the part with a scale, caliper, micrometer and dial indicators are required.

5. I.D. Work Is Even More Difficult To Measure “Blind”

Difficult set-ups of indicators and magnetic base holders are time consuming, and always run the danger of being bumped or moved.

6. Step Lengths

Since reading the carriage travel is even more difficult with the lathe’s vernier dial, due to its location (some lathes do not even have a dial on this axis), stop-and-measure is a must. Travel-type dial indicators are a small improvement, but are hard to read. They can jump and skip due to chips getting caught under the friction wheel, which must be held under compression against the lathe carriage way to spin the dial.

Why Your Lathe Needs a DRO

Vastly Reduced Positioning Time

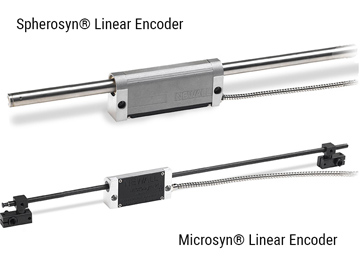

Digital Readouts (DRO's) utilize linear scales mounted to the cross-slide and carriage axis of the lathe. The scale reads position independent of the lead screw and shows the true tool position, regardless of mechanical wear and backlash. Reading lines on vernier dials, counting hand wheel revolutions and lead screw backlash compensation are eliminated.

Greater Accuracy and Repeatability

The accuracy and repeatability of precision linear scales allow the operator to position the tool to the print dimensions – just like the print reads. Stop-check-measure steps are all but eliminated. Features like direct diameter reading greatly reduce mathematics, calculations and scrap due to operator error. Less time checking and measuring means more time making chips.

Productivity improvement of 20-40% typically reported using DRO on lathes.

Why Choose a Newall DRO for Your Lathe?

Lathework is a Harsh Environment

Most lathe work is exposed to a high volume of chips, coolant and other potentially hazardous conditions, more so than other machining operations, such as milling.

If The Scale Doesn’t Work, Neither Does The DRO

DRO display features are helpful, but the main DRO benefit is derived from independence of lead screw wear and backlash, which the linear scales provide.

Glass or Magnetic (Wire or Tape) Scales Can Fail In the Lathe Environment.

Glass Scales can scratch, break or misread due to condensation and contamination from chips, coolants and lubricants. Magnetic wire and tape scales fail due to chip build up or loss of polarity.

Newall Offers the Most Durable DRO System Available

- IP67 rated & fully submersible

- Withstand dust, dirt, oil and other harsh environmental conditions

- No mechanical wear characteristics

- No cleaning or maintenance

- High tolerance to shock and vibration

3 Models to Meet Your Application Needs

Newall offers 3 lathe DRO models to meet your application needs. The DP500 is a low-cost DRO system that was designed specifically for tool room lathes. If you need more features or longer travel lengths, take a look at the DP700. It offers more advanced features typically only found in a higher priced DRO System. For long travel lathes the DP1200 fits the bill. The larger screen size will allow your operator to read the position of each axis easily from a distance. If you have a large lathe with travels over 500" - give us a call. We can special order Lathe Digital Readout Systems for the DP700 and DP1200. All of our pricing is listed online. If you have any questions or want to negotiate custom pricing for a bulk order please give us a call.