Sizing a Newall Digital Readout Kit for your lathe or mill is quick and easy. Below you will find step by step instructions on how to measure the travel on a turning machine. The process is almost exactly the same for a mill. See Mill Page Here. Remember when ordering Newall Digital Readouts or Newall Linear Encoders, the scale is sold based on travel length, but the overall length of the scale is actually longer. For Spherosyn Encoders (shown below) the overall length is equal to the travel + 10". The overall length of a Microsyn Encoder is travel + 7". Make sure to take this into consideration when sizing a Newall DRO Kit for your machine.

Step 1: Slide the Tailstock and any stops to their most outward position. Traverse the saddle to its maximum travel towards the chuck.

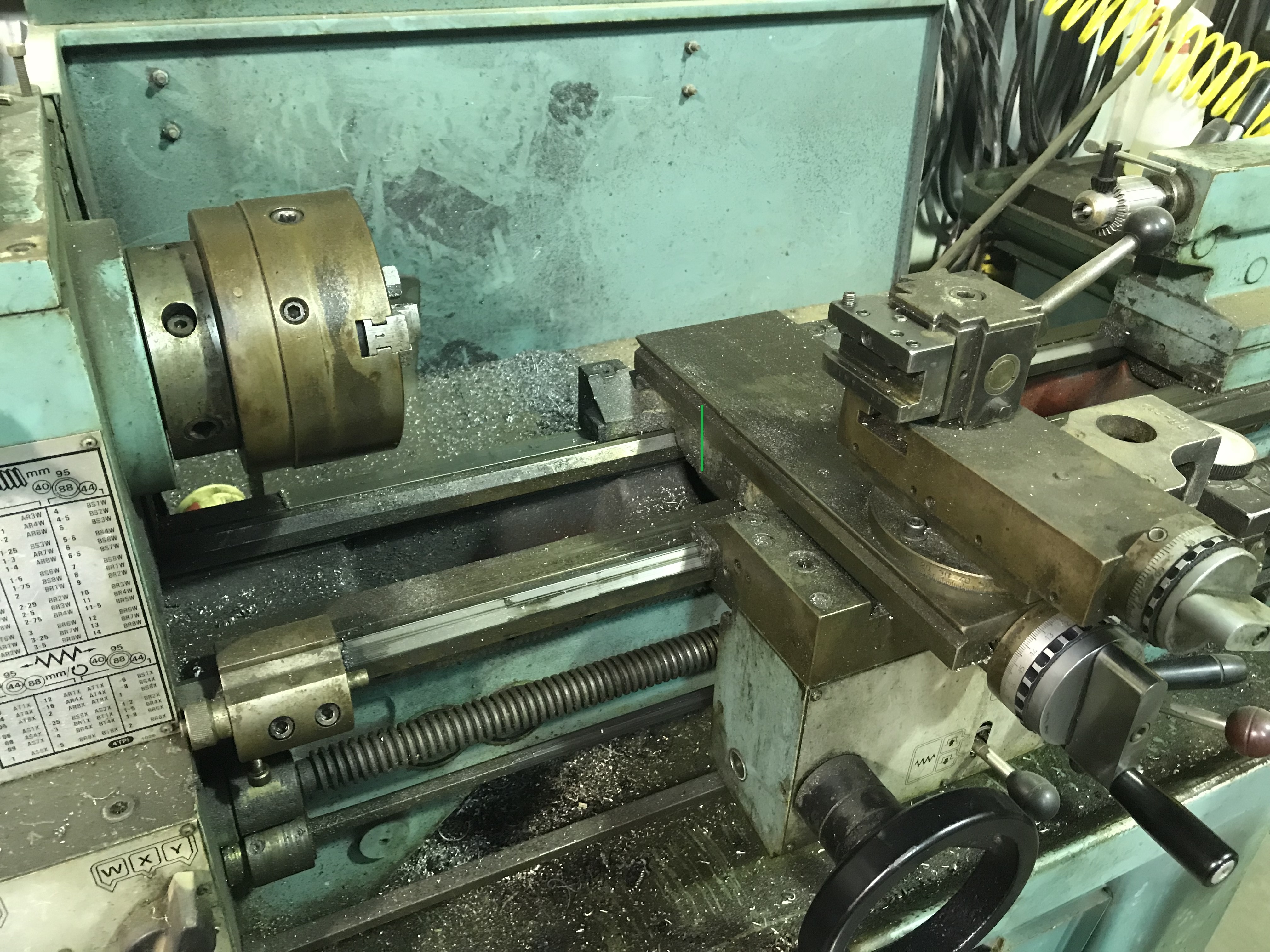

Step 2: Draw a line along the inside edge of the carriage on the bed.

Step 3: Traverse the carriage to its full extent toward the tail stock

Step 4: Measure between the mark and the edge of the carriage (inside edge)

This will give you the carriage travel. Our carriage travel was 23". NOTE: Normally the machine is designed such that the carriage travel is at its extent before coming into contact with the tailstock at its most rear position.

Step 5: Traverse the cross slide to its most outward position

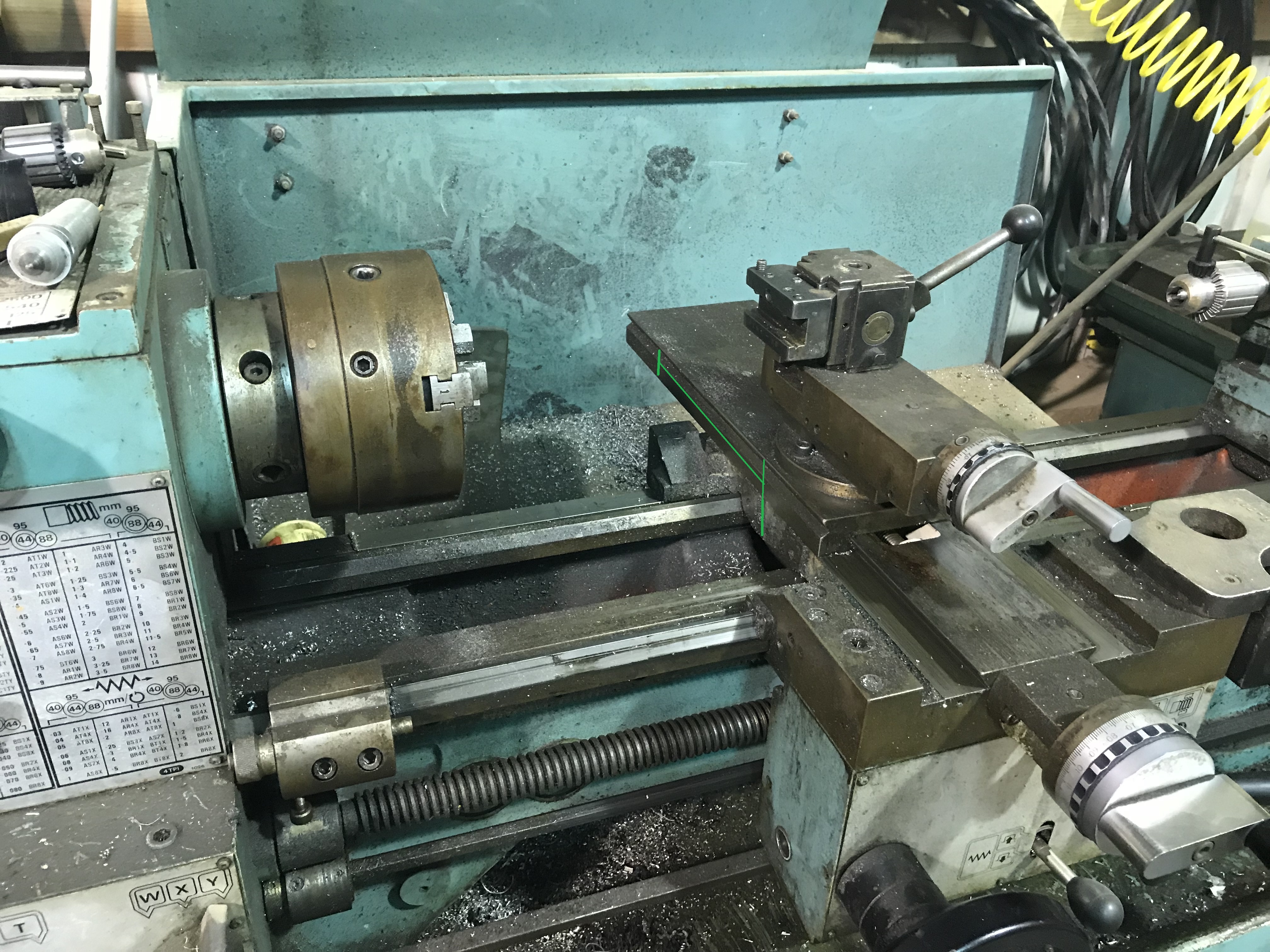

Step 6: Draw a line across the cross slide and lower slide

Step 7: Traverse the cross slide to its most inward position.

Step 8: Measure between the two marks, this is your cross slide travel

Our Cross Slide travel was approximately 7.5" so we would go with a 6" x 30" Package with single end mount on the 6" (giving us 8" of travel).