Description

Get Fast & Easy Retrofit Financing

![]()

Get instant funding with low monthly payments

Get instant funding with low monthly payments

Unfortunately we do not perform retrofits outside of the United States, Canada, and Mexico at this time

With over 700,000 systems installed, the Fanuc 0i CNC is the world’s most popular CNC model. The latest, most powerful Series 0i-TF/MF is designed for commodity machines that demand the ultimate in reliability, performance, connectivity and safety. The Series 0i-F provides over 200 high-value features in the standard configuration and is perfect for CNC retrofit applications.

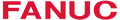

The Fanuc 0i control system uses high-performance hardware and innovative software to guarantee high performance, accuracy, surface finish and reliability.

A wide range of industry-standard protocols are supported by the Fanuc Series 0i-TF/MF CNC. This allows for low-cost and flexible integration with manufacturing and business systems, including Ethernet, FTP, DeviceNet and Profibus. Dual check safety is also fully supported.

Fanuc 0i-F is perfect for a range of CNC retrofit applications

The Fanuc 0i control platform is perfect for retrofitting all types of machine tools including lathes, machining centers, grinders, punch presses and routers.

Over 200 high-value features

The Series 0i-TF and Series 0i-MF are value packaged with over 200 high-value features including nano interpolation, embedded Ethernet, extended and background editing, Custom Macro with additional variables, high-speed skip, thread cutting, rigid tapping, feed-per-rev programming, tool radius compensation, tool management and multi-language display with dynamic switching. The 0i-TF also includes polar coordinate interpolation, multi-threading, thread cutting retract, continuous threading, variable lead threading, Advanced Preview Control, multiple repetitive cycles, tool geometry and wear compensation. The 0i-MF also includes helical interpolation, AI Advanced Preview Control, canned cycles for drilling, scaling, 400 tool offset pairs and 48 workpiece coordinate offset pairs.

Ultimate resolution and precision for quality machining

The CNC and drive system executes at a nanometer resolution all the way down to the 16-million count encoders for the maximum precision and the smoothest contoured surface finish quality.

High-speed machining for quality and reduced cycle times

Advanced software algorithms analyze part geometries and machine capabilities and adjust trajectories and feedrates to provide the smoothest tool paths for the highest processing speed at the specified precision.

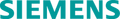

The Fanuc Series 0i-F comes with plenty of network support functions

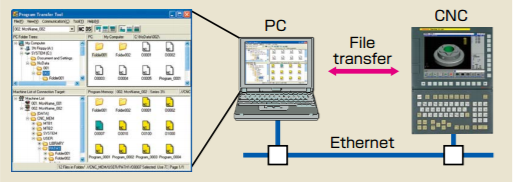

With plenty of network functions, you can construct an optimum system formachine tools. Embedded Ethernet of 100Mbps is supported on the CNC main board. CNC can be connected to a personal computerto transfer NC programs and monitor CNC status.The Fast Ethernet board can be mounted as an option. Data can be transferred simultaneously among multiplecomputers at high speed. These features are ideal to construct a production system which exchanges informationamong machining lines and factory host computer.

Easy preventative maintenance functions for minimizing downtime

Insulation deterioration sometimes causes a machine tostop due to cutting fluid infiltrating the motor, especiallyin a severe machining environment. The leakagedetection function built-in amplifier automaticallymeasures insulation resistance of the motor, anddetects insulation deterioration when it comes to anabnormal level, thereby preventing machine fromunexpected stop. In addition, cooling fan warning functions will detect a decrease in rotational speed of each cooling fanmotor of the CNC and the amplifier is detected as a warning. By this function,deterioration of the fan are detected and can be replaced before fan stops.Fans are stored in a cartridge and can be replaced quite easily, somaintainability is enhanced.

Powerful software tools for simulation and data management

FANUC NCGuide is a software tool that enables training of CNC operations on a PC. It allows operators to be trained without usingan actual machine tool.FANUC Program Transfer Tool is a softwaretool for transferring part programs and data byconnecting PC and CNC via Ethernet.Files in the CNC program memory are displayedon the tool in an easy-to-understand way, soinput/output operation can be easily performedwith a mouse.

Maintenance and Customer Support

As an integrator we have completed hundreds of retrofits in the United States, Mexico, and Canada. We are extremely proud of the fact that we don't just offer machine tool retrofits - we offer turnkey solutions that leave our customers with little to do when it comes to retrofitting their machines. All of our CNC retrofit solutions include factory warranty on all hardware - including CNC, drives, and motors. We also offer 24/7 support for the life of the control system, so you can be sure that you'll have the support you need to keep your machine up and running.

Request a Free Quote

We would love to work with you on your next retrofit project. To receive a free quote for a Fanuc turnkey CNC retrofit solution, please click the red "Request Quote" button above and provide your contact information and a brief overview of your retrofit application. Once we receive your RFQ one of our Controls Engineers will contact you to discuss your application in more detail. We look forward to working with you!

Download the Fanuc 0i Model F CNC Catalog

Reviews (0)

Be the first to review this product.

Additional Info

- Warranty:

- <a href="http://machinetoolproducts.com/content/Fanuc/Fanuc%200i-F%20CNC%20Catalog.pdf" target="_blank">Fanuc 0i Model F Catalog</a>

- SKU:

- TKR-FANUC-0IF

- Availability:

- 8-12 weeks (expedite services available)